We have a new website!

This website will be terminated over time as we can not add more load data. Hence, we have setup a new website with even more load data and additional features under www.xxlreloading.com.

Innovative

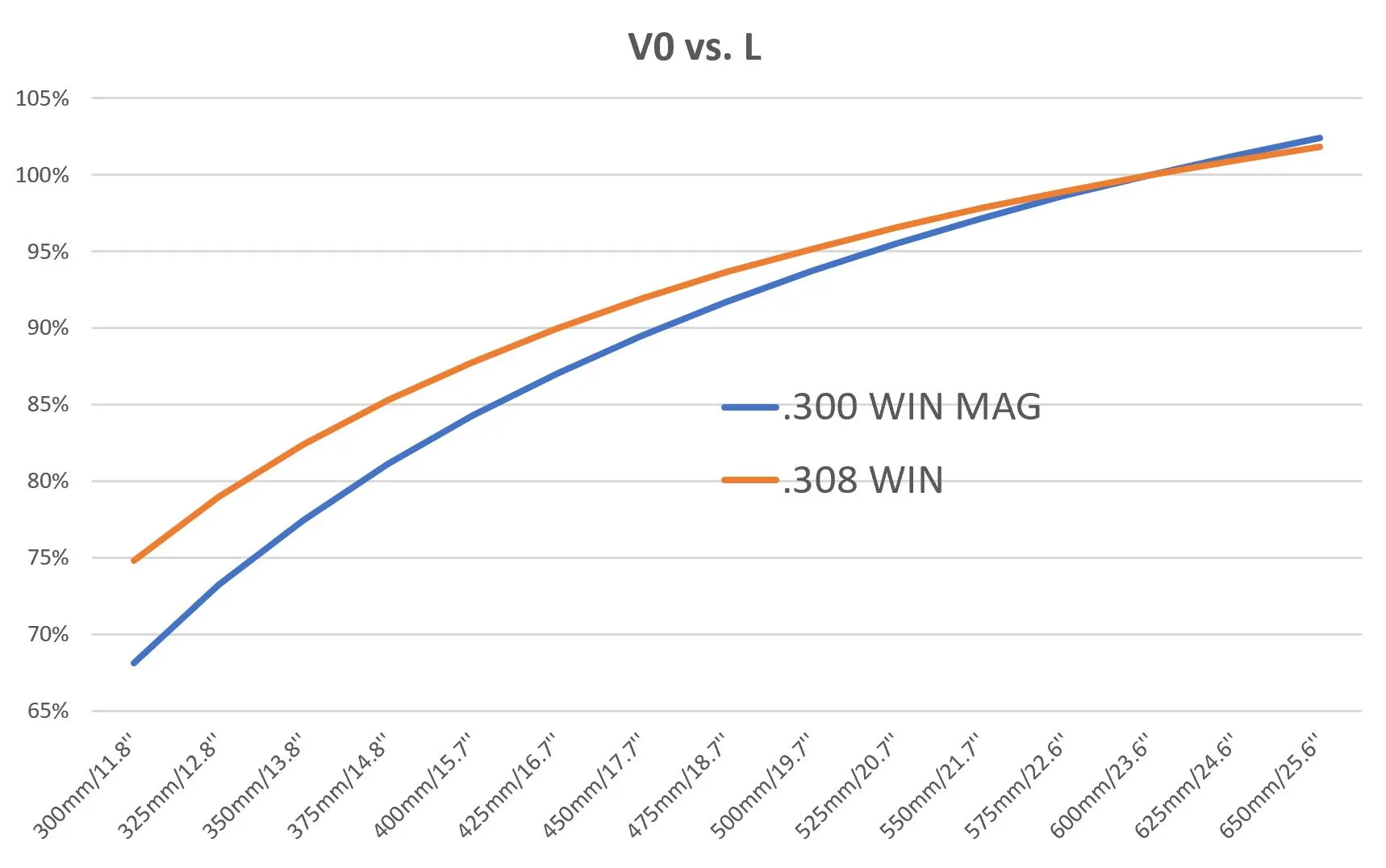

Easily compare performance of different powders and see impact of varying barrel length.

Independent

We offer extensive load data for bullets and powders of various brands in one place.

Powerful

We operate very sophisticated and powerful ballistic models on high-end computers.

XXL Online Load Database

Popular Reloading Calibers

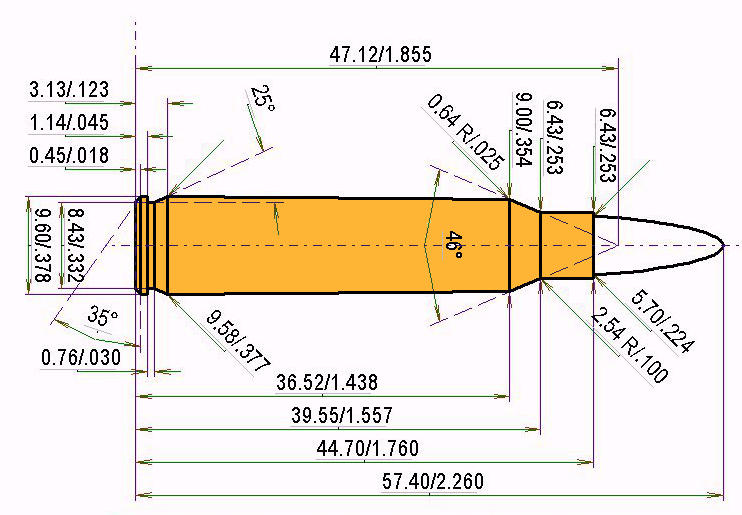

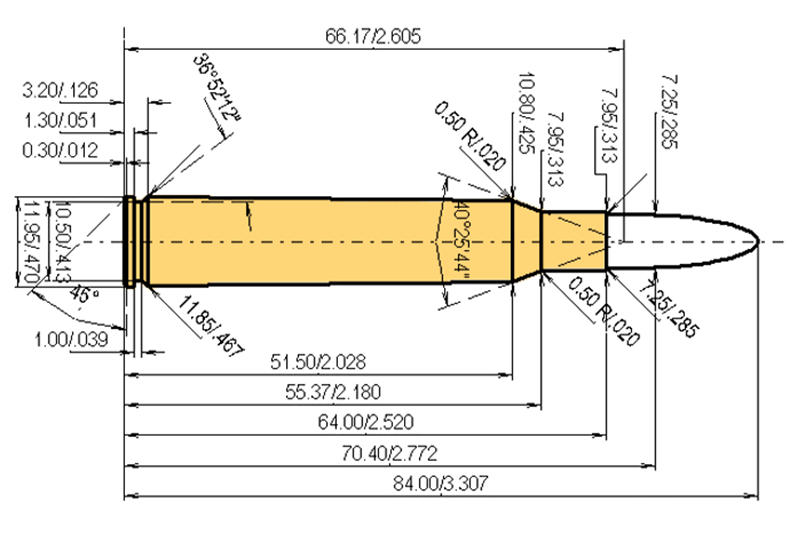

Max. Case Length (l3): 1.76'' | 44.68 mm

Maximum Standardized Pressure: 54970.16 psi | 3790 bar

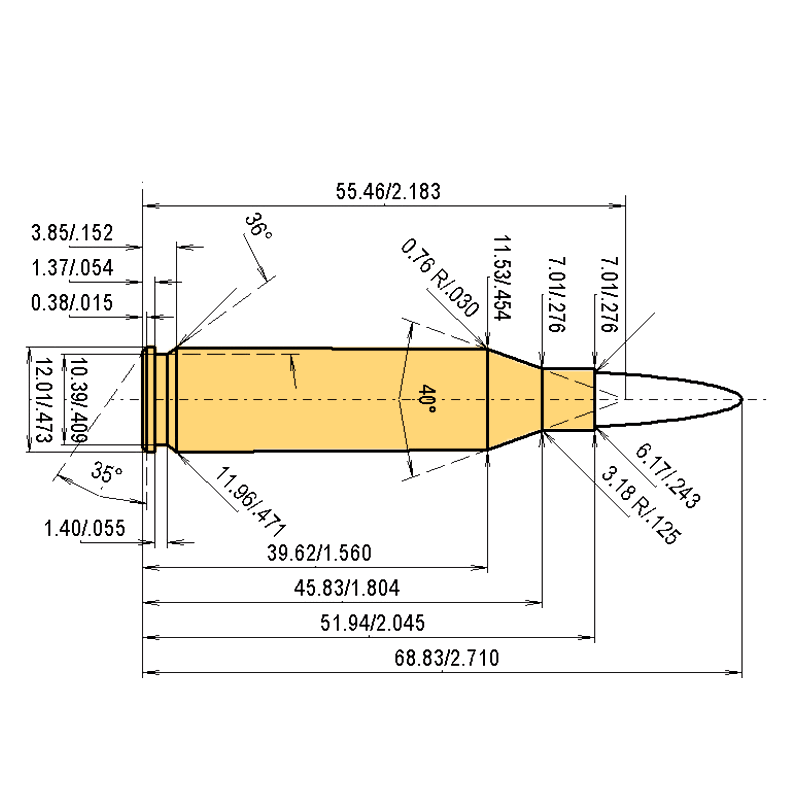

Max. Case Length (l3): 2.04'' | 51.92 mm

Maximum Standardized Pressure: 60191.6 psi | 4150 bar

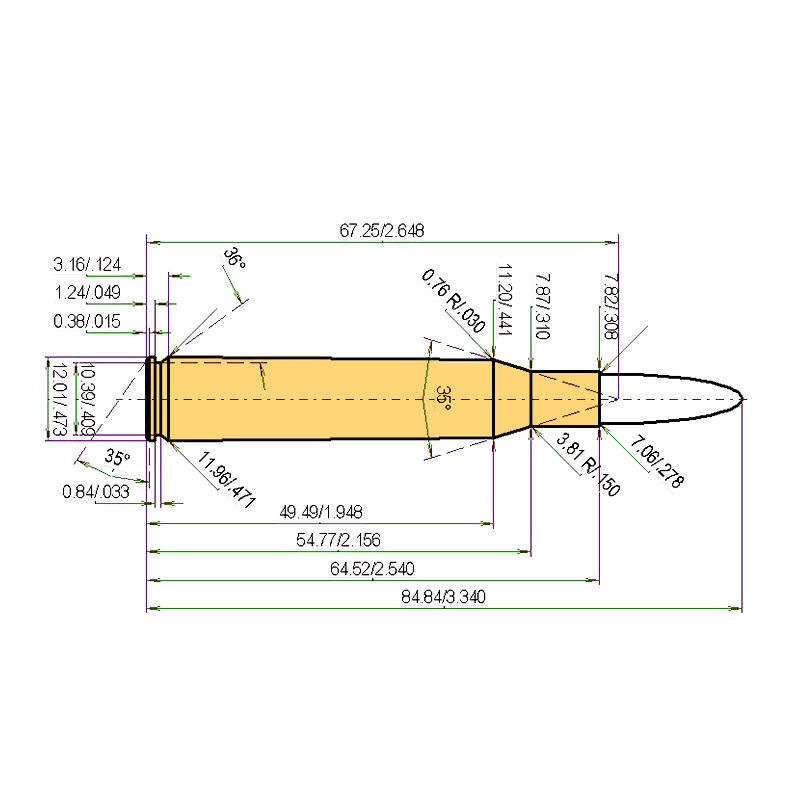

Max. Case Length (l3): 2.54'' | 64.52 mm

Maximum Standardized Pressure: 62367.2 psi | 4300 bar

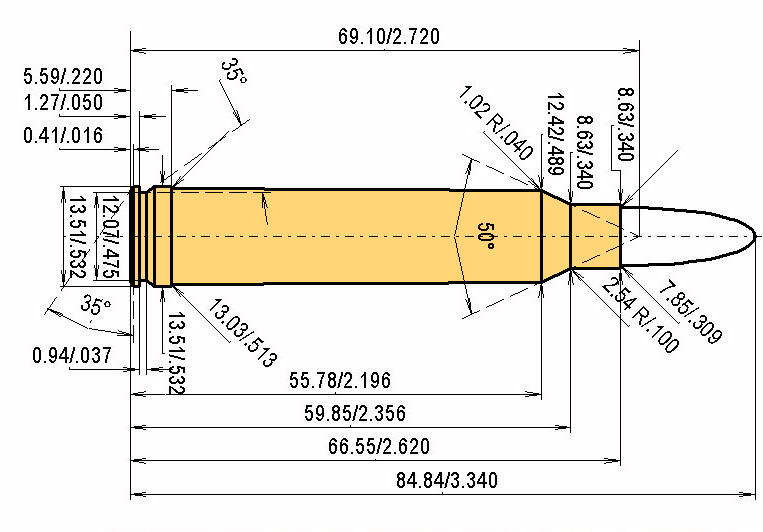

Max. Case Length (l3): 2.62'' | 66.55 mm

Maximum Standardized Pressure: 62367.2 psi | 4300 bar

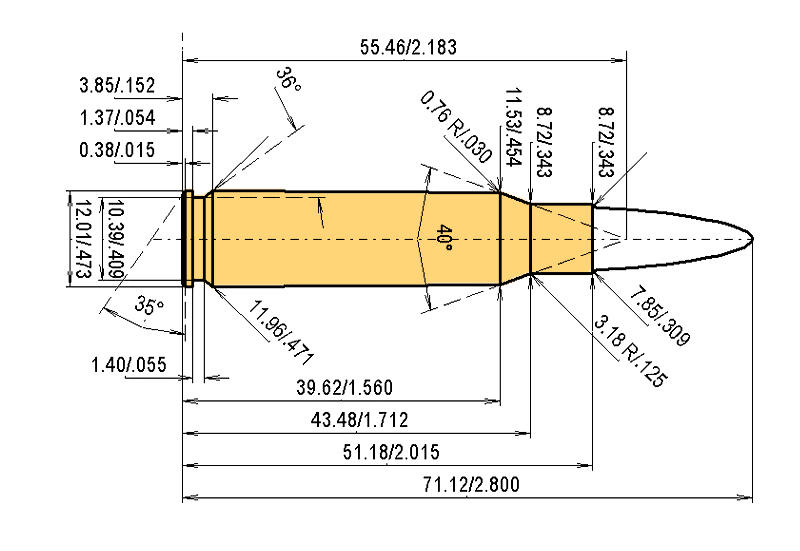

Max. Case Length (l3): 2.01'' | 51.16 mm

Maximum Standardized Pressure: 60191.6 psi | 4150 bar

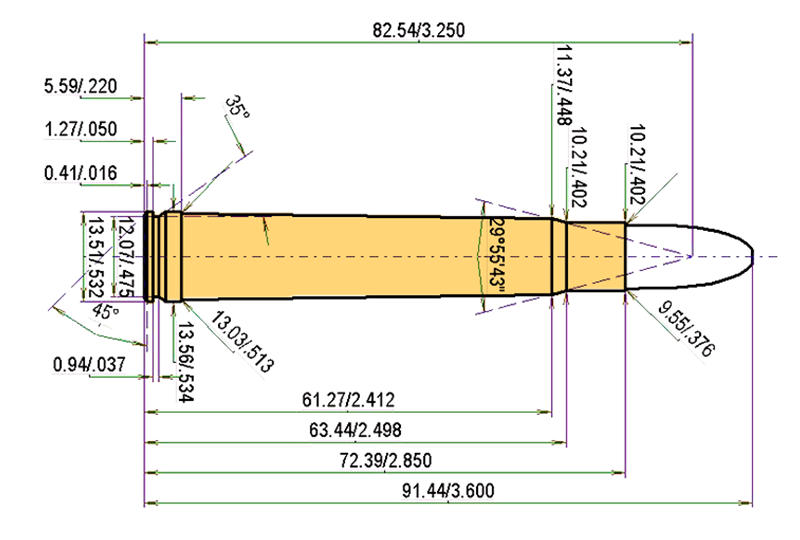

Max. Case Length (l3): 2.86'' | 72.62 mm

Maximum Standardized Pressure: 62367.2 psi | 4300 bar

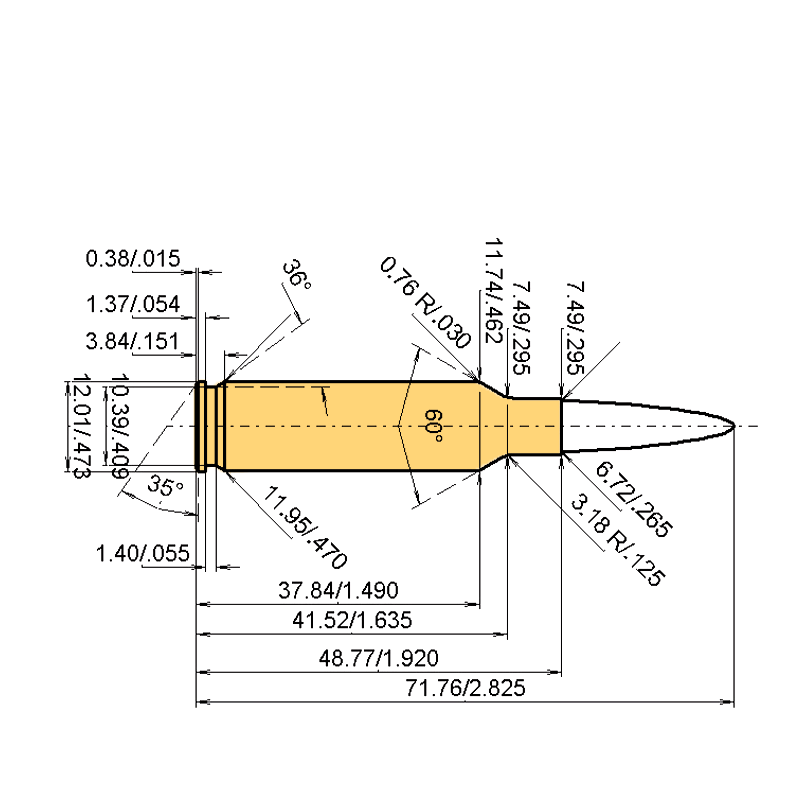

Max. Case Length (l3): 1.92'' | 48.77 mm

Maximum Standardized Pressure: 63092.4 psi | 4350 bar

Max. Case Length (l3): 2.52'' | 63.98 mm

Maximum Standardized Pressure: 60191.6 psi | 4150 bar

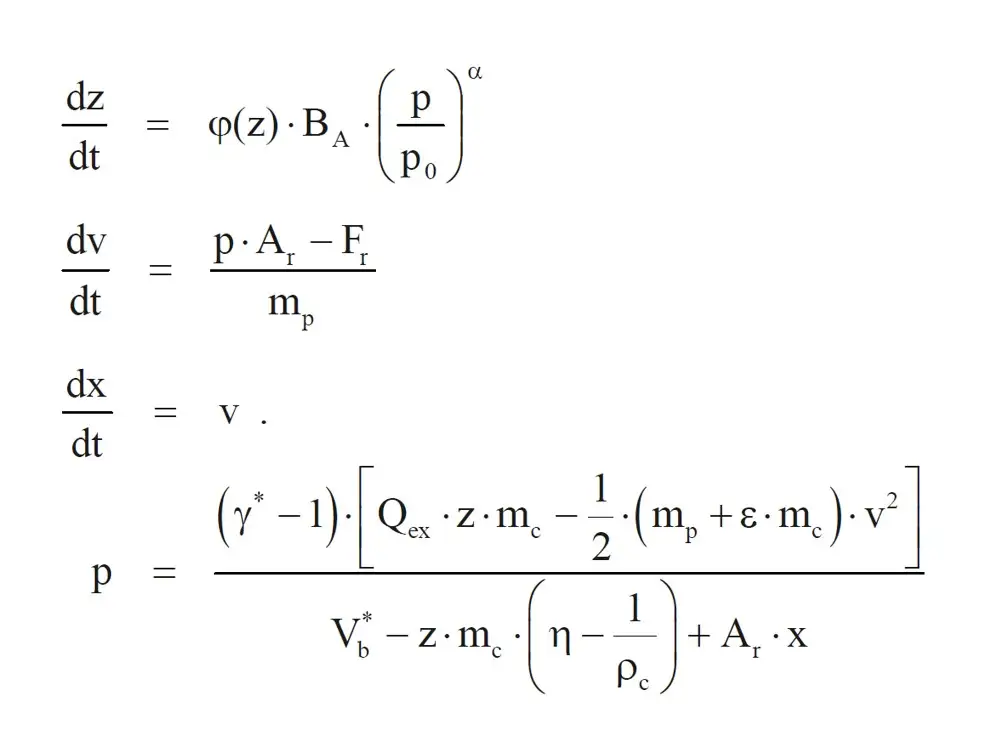

Ballistic- and Powder-Models

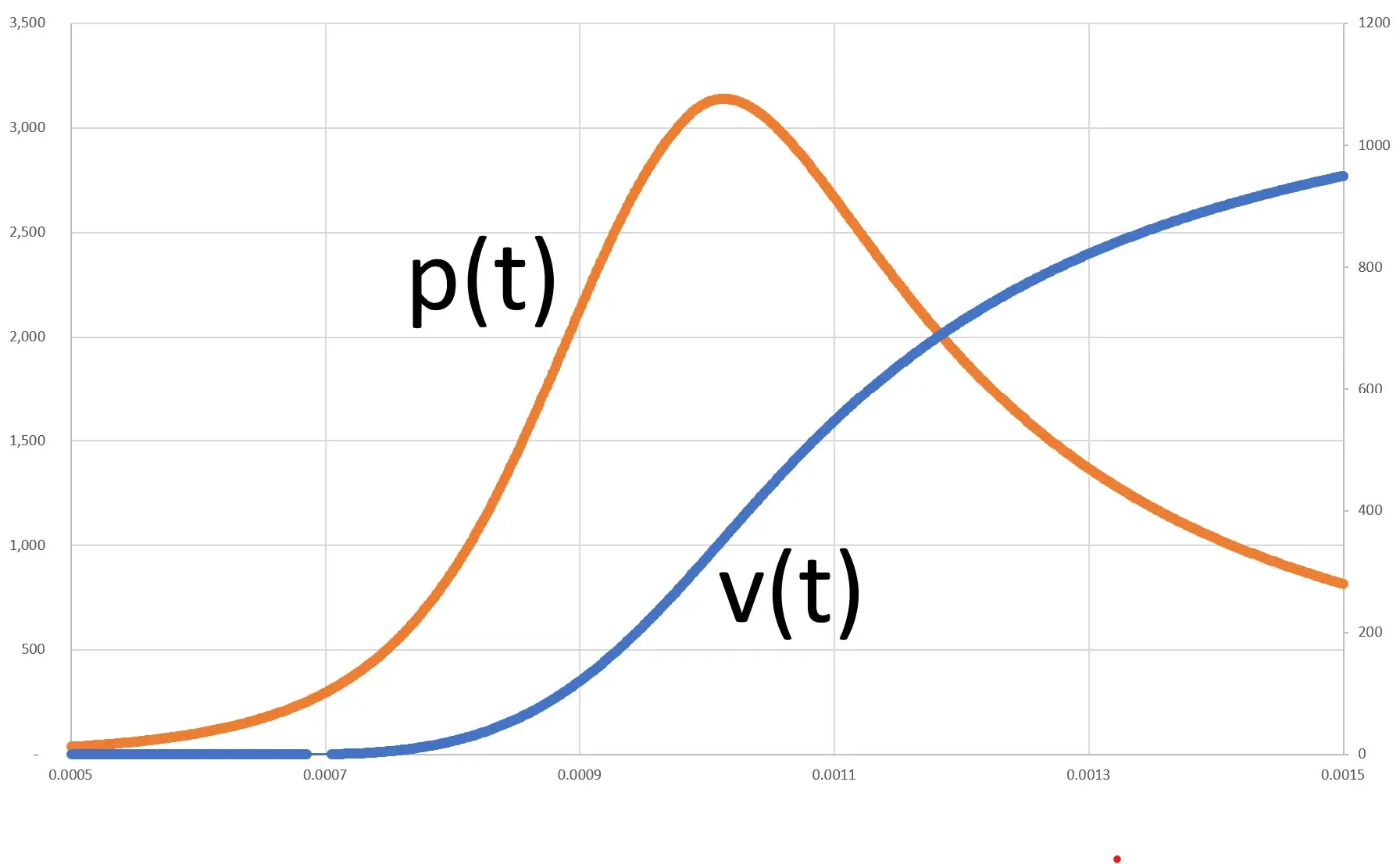

Our highly sophisticated ballistic calculator takes all relevant aspects into account such as powder properties, bullet and cartridge dimensions. The underlying models are discussed in detail in the relevant literature. The art is to calibrate these models based on real tests to improve accuracy. We worked with one of the most well-known experts in this field to optimize our models. Other existing ballistic calculators have often been developed based on old programming languages and limited proecssing capacities of historical computers. Our models run on high-end cloud servers which allow us to do more iterations for better results.